Vacuum Insulated Panels (VIP)

Ultra-high-performance thermal insulation panels engineered to deliver exceptional insulation efficiency in extremely space-constrained applications.

Why Vacuum Insulated Panels Are Used

In applications where conventional insulation materials cannot meet thermal performance requirements within limited space, Vacuum Insulated Panels provide a decisive advantage.

By combining a micro- or nano-porous core with a vacuum-sealed barrier, VIPs drastically reduce heat transfer, achieving insulation performance several times higher than traditional materials at a fraction of the thickness.

Extremely low thermal conductivity

Maximum insulation performance at minimal thickness

Ideal for space- and weight-critical designs

Enables compact, energy-efficient systems

Wedge Vacuum Insulated Panel Solutions

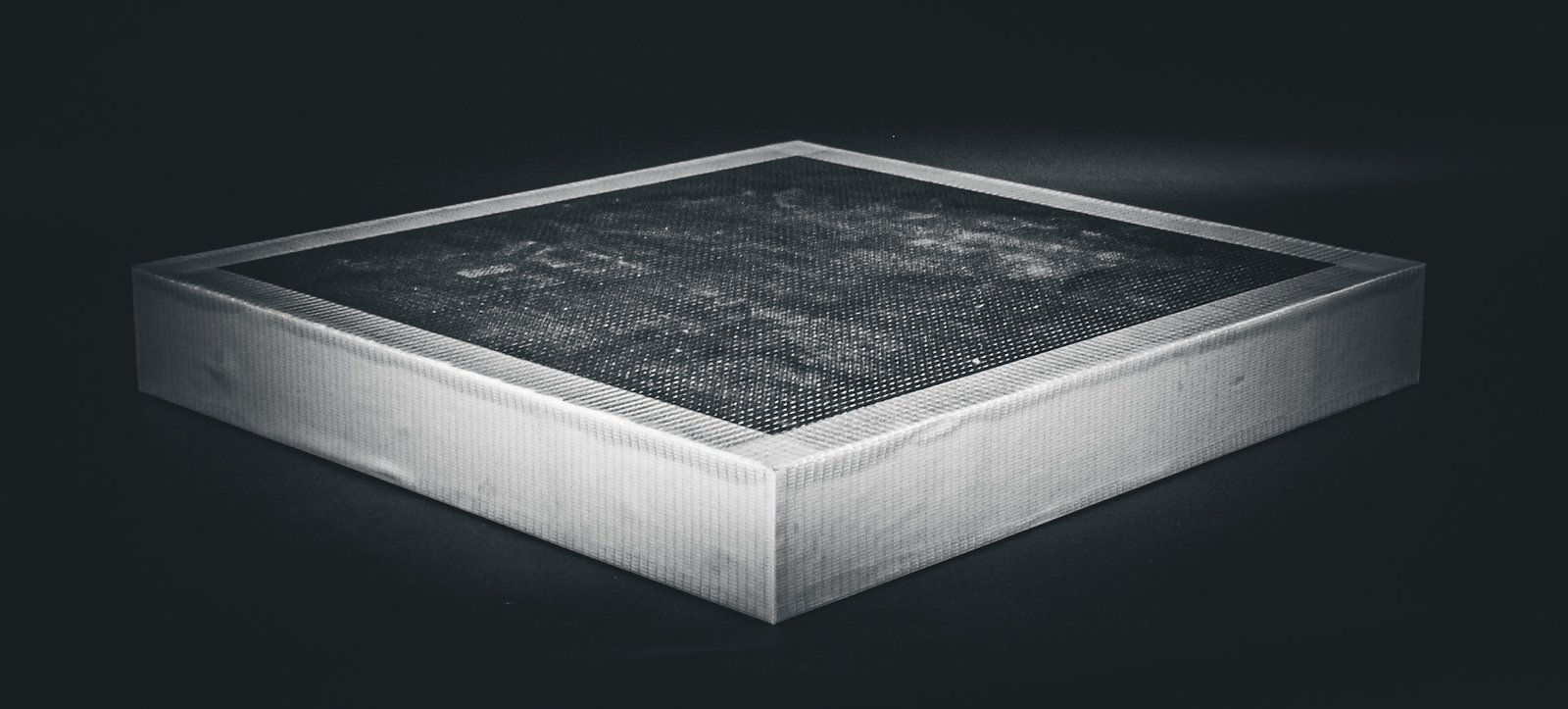

WedgeVac vacuum insulated panel (VIP) is a form of thermal insulation consisting of a gas-tight enclosure surrounding a rigid core, from which the air has been evacuated. It is used in building construction, refrigeration units, and insulated shipping containers to provide better insulation performance than conventional insulation materials. Vacuum insulated panel VIP insulation panels good quality low price cold box food storage vaccine transport freezer building at Wedge India.

Wedge designs and manufactures Vacuum Insulated Panels tailored for high-performance thermal control in demanding industrial, infrastructure, and energy applications.

Our VIP solutions integrate engineered porous cores, high-barrier encapsulation, and precision manufacturing to ensure reliable thermal performance and long-term stability.

Custom-sized Vacuum Insulated Panels

Rigid, flat-panel formats for system integration

High-barrier encapsulation for thermal durability

Panels designed for integration into composite systems

Engineering support for application-specific designs

Key Performance Characteristics

Ultra-low thermal conductivity (VIP-class performance)

Exceptional insulation efficiency per millimeter

Stable performance in controlled operating environments

Compatible with multi-layer insulation systems

Designed for long-term thermal efficiency

Typical Applications

Energy-efficient building envelopes

Refrigeration and cold-chain systems

Data centers and precision thermal zones

EV and battery thermal systems

Industrial equipment with strict space limitations

High-performance infrastructure projects

How Vacuum Insulated Panels Compare to Conventional Insulation

Vacuum Insulated Panels deliver significantly higher thermal resistance than conventional insulation materials at reduced thickness, enabling design flexibility and superior energy efficiency where space constraints are critical.

Multiple times higher insulation efficiency per thickness

Reduced system size and weight

Enhanced energy retention

Enables compact, high-performance designs

Why Wedge for Vacuum Insulated Panels

Wedge approaches Vacuum Insulated Panels as precision-engineered components rather than off-the-shelf products.

Our expertise in porous materials, encapsulation technologies, and system integration enables us to deliver VIP solutions aligned with real-world operating conditions, performance expectations, and long-term reliability.