Microporous Insulation

Microporous porous insulation are Ultra-low thermal conductivity insulation systems engineered for extreme thermal control where space, efficiency, and precision are critical.

Why Microporous & Nano-Porous Insulation Is Used

In high-temperature and high-performance systems, traditional insulation materials often fail to deliver the required thermal efficiency within limited space.

Microporous and nano-porous insulation materials are engineered to dramatically reduce heat transfer by restricting conduction, convection, and radiation at the microscopic level — enabling exceptional insulation performance in compact, demanding environments.

Extremely low thermal conductivity

High insulation performance at minimal thickness

Effective at elevated temperatures

Ideal for space-constrained and precision applications

Wedge Microporous & Nano-Porous Insulation Solutions

Wedge FSMP® Microporous Insulation – Made in India

Wedge India is proud to introduce FSMP® Microporous Insulation, India’s first locally manufactured, high-performance microporous insulation solution engineered for extreme temperature applications up to 1200 °C. Designed with ultra-low thermal conductivity, FSMP® delivers 4–5× better performance than conventional insulation materials—allowing the same insulation capacity at up to 75% less thickness.

Why Choose Wedge FSMP® Microporous Insulation?

Ultra-Low Thermal Conductivity: As low as 0.021 W/m·K at high temperatures, surpassing mineral wool, calcium silicate, and ceramic fiber.

Space-Saving Design: Achieve required thermal performance with minimal thickness—ideal for space-constrained applications.

High-Temperature Resistance: Rated up to 1200 °C for continuous service.

Non-Combustible & Safe: A1 fire-rated, free from harmful respirable fibers, and environmentally friendly.

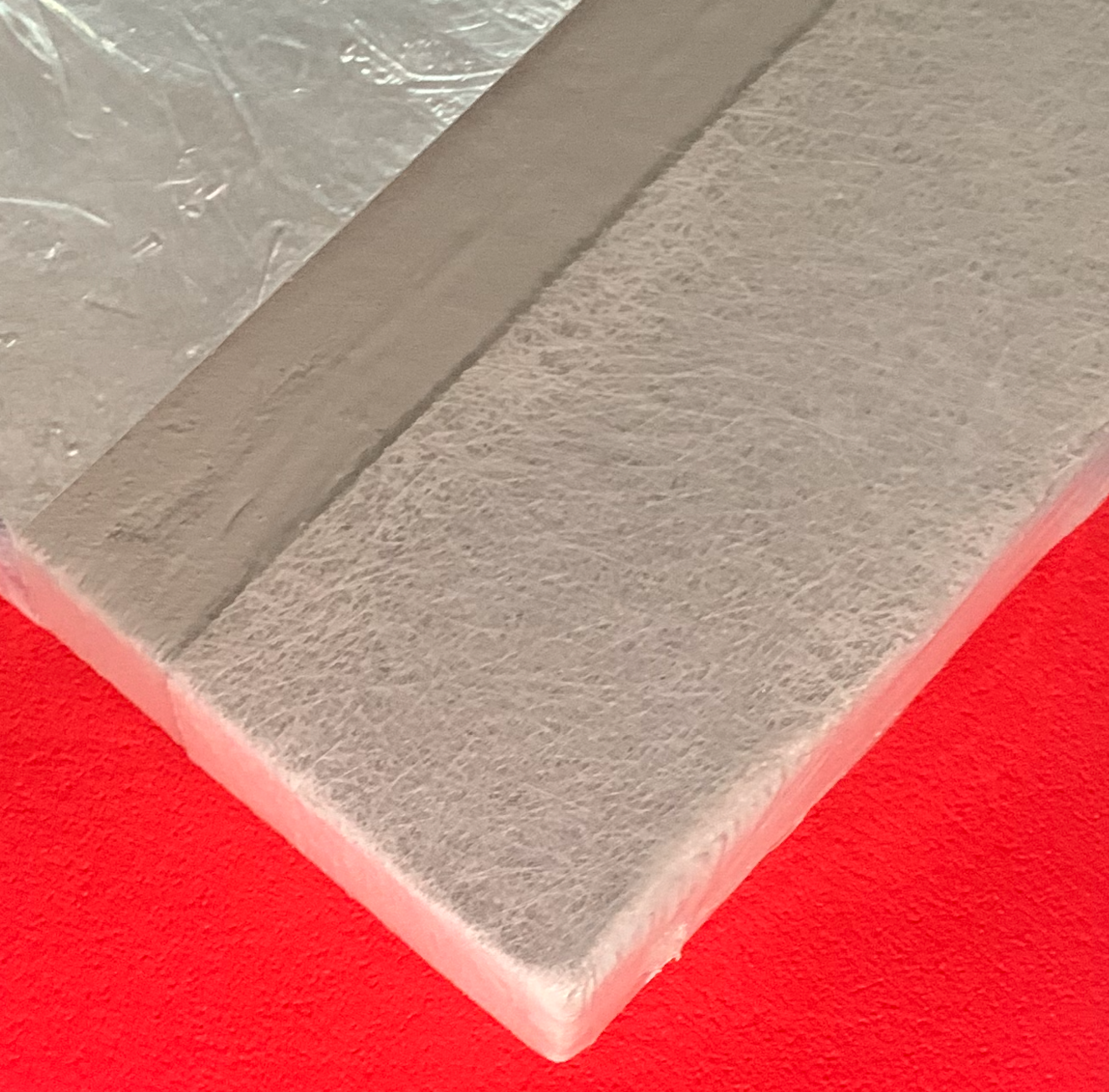

Customizable Formats: Available as rigid boards, flexible blankets, quilted panels, and molded pipe sections.

Hydrophobic Options: Repels water for use in wet or condensation-prone environments.

Made in India Advantage: Faster delivery, lower cost, and local engineering support.

Microporous insulation is high-temperature insulation, which provides extremely low thermal conductivity over a temperature ranging from 0.021 w/m.k (watt/meter/Kelvin temperature) to 0.034 w/m.k at a mean temperature of 800°C.

Microporous insulation 1200 grade boards are high-performance thermal insulation materials designed to provide exceptional thermal management in extreme temperature environments. These boards have extremely low thermal conductivity and are engineered for applications that demand superior insulation properties.

Properties of 1200 Grade Microporous Insulation Boards

Microporous insulation panels and boards

Nano-porous composite insulation systems

Flexible and rigid formats

Encapsulated insulation modules

Custom-engineered solutions for OEM and industrial use

Technical Specifications for 1200 Grade Microporous Insulation Boards

- Thermal Conductivity: Typically around 0.020 W/m·K at 200°C (varies by manufacturer and specific product)

- Maximum Service Temperature: Up to 1200°C or higher

- Density: Generally around 300-400 kg/m³ (varies by product)

- Compressive Strength: High, ensuring durability under mechanical stress

- Chemical Composition: Typically includes fumed silica, opacifiers, and inorganic fibers

Key Performance Characteristics

Ultra-low thermal conductivity

Stable performance at high temperatures

Minimal thickness for maximum insulation efficiency

Low heat storage and fast thermal response

Compatible with industrial and energy systems

Typical Applications

Industrial furnaces and kilns

High-temperature process equipment

Energy and power generation systems

EV battery and thermal protection systems

Data centers and precision thermal control zones

Aerospace, defense, and advanced manufacturing

Why Wedge Microporous Insulation Outperforms Conventional Materials

Wedge approaches microporous and nano-porous insulation as a precision engineering solution rather than a standard material supply.

Our material formulation expertise, manufacturing control, and systems-engineering mindset allow us to deliver insulation solutions optimized for real-world operating conditions, regulatory requirements, and long-term reliability.

Compared to conventional insulation materials, microporous and nano-porous systems deliver significantly higher thermal resistance at reduced thickness, enabling design flexibility and superior energy efficiency in extreme environments.

Higher insulation efficiency per millimeter

Reduced space and weight requirements

Improved thermal control at high temperatures

Enhanced system performance and safety